Yielding excellent wear and corrosion resistance electroless nickel is an autocatalytic plating process resulting in a reflective layer of nickel phosphorous.

Electroless nickel plating aluminum thickness.

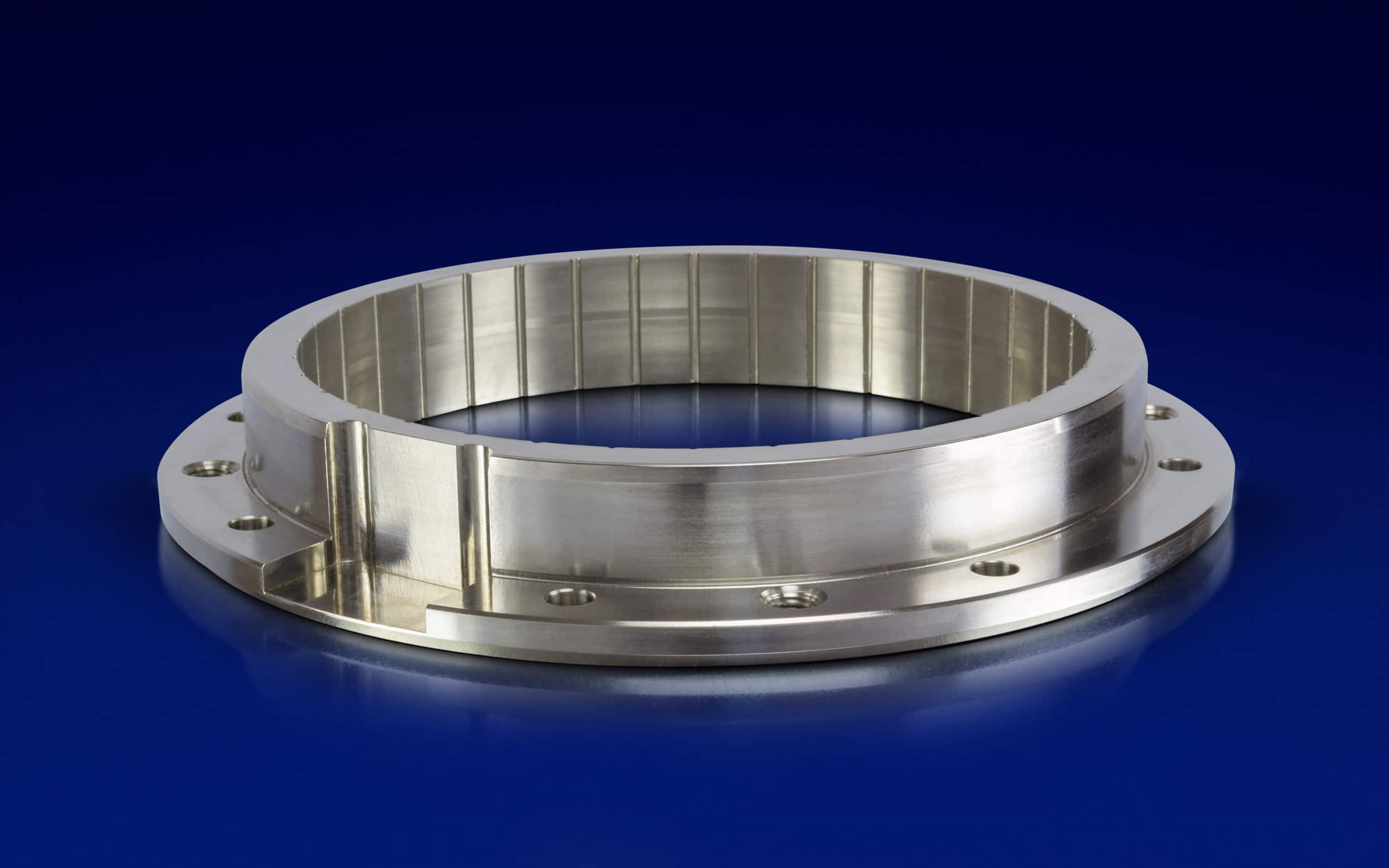

We apply high precision electroless nickel plating composite nickel coatings and boron nitride for industrial applications requiring corrosion protection high hardness wear resistance uniform thickness and increased dry lubricity on parts from ounces to 300 lbs.

Adv plates all substrates including aluminum brass steel and cast iron and offers high medium and low phosphorous finishes as well as ptfe and black en.

En provides uniform thickness with a tight tolerance.

It is the most common version of electroless nickel plating.

The phosphorus content has a.

And electroless nickel that are associated with their purity and structure.

The electroless nickel plating process utilizes an autocatalytic chemical reaction to deposit a reliable repeatable coating of uniform thickness.

First developed in the 1940s electroless nickel en plating is used heavily by automotive and aviation for corrosion and wear resistance.

Mil c 26074 astm b733 ams 2404 iso 4527.

It is a coating with multi functional properties.

Our series 200 electroless nickel plating coatings are applied via a time controlled deposition process which allows us to specify a wide range of thicknesses and hold tight tolerances.

For instance the purity of electrodeposited nickel is typically greater than 99 but when sodium hypophosphite is used as a reducing agent in electroless nickel plating a typical composition for the deposit is 92 nickel and 8 phosphorus.

Electroless nickel plating can increase hardness and improve wear and corrsion resistance.

Depending on your application requirements we routinely apply coatings as thin as 0 0002 per surface or as thick.

Below is a brief overview of the electroless.

The total build up plating process provides uniformity on all surfaces making post machining unnecessary when dimensions are accurate.

Electroless nickel plating is the deposition of a nickel phosphorous alloy onto a metal substrate without the use of an electrical current.

The electroless nickel phosphorous content affects the properties of the deposit significantly including hardness corrosion resistance and magnetism.

During the electoles nickel plating process the autocatalytic reaction between nickel and reducing agent in the plating bath deposits nickel onto.

Typical substrates plated include carbon steel stainless steel copper alloys and aluminum alloys.

Hardness heat hardenability solderability electrical conductivity and abrasion wear and corrosion resistance.