These secondary systems must have sufficient volume to hold all of the primary tank s liquid capacity plus a hefty extra percentage to ensure proper containment.

Do double wall tanks need secondary containment.

This guidance also clarifies when shop built double walled asts satisfy the applicable secondary containment requirements in the spill prevention control and countermeasure spcc rule found at 40 cfr part 112.

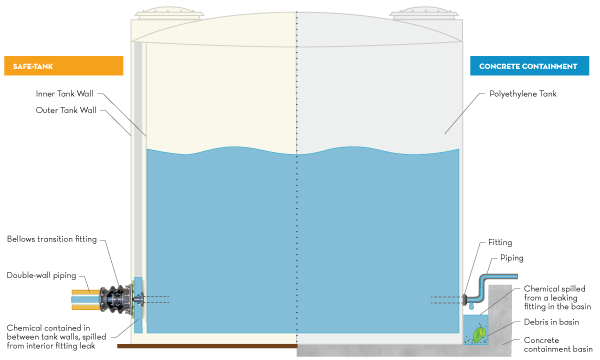

The outer tank provides the secondary containment to the primary inner tank.

Double wall tanks have the added benefit of keeping rainwater out.

Double wall plastic storage tanks have their own secondary containment.

An owner or operator of a facility can self certify and their spcc plan if they qualify as a tier i or tier ii facility.

The epa refers to the need for containment and secondary containment in two different areas.

Such as a tank or pipe will not escape the containment.

Typically secondary storage will be a dike system concrete vault or double wall steel storage tank.

Inner tank dome overlaps outer tank sidewall to prevent rainwater snow and debris from entering into the containment basin.

Use of certain double wall aboveground storage tanks asts for secondary containment purposes.

A copy is attached for your reference.

And capacity for secondary containment you need only to address the typical failure mode and the most likely quantity of oil that would be discharged.

Chapter 4 secondary containment and impracticability.

Owners and operators must inspect the inner wall and interstitial spaces of a shop built double wall ast using industry standards such as the sp001 00 standard for inspection of in service shop fabricated aboveground tanks for storage of combustible and flammable liquids.

If your tank is outside you will not have to worry about the weather.

Having double walled tanks or other devices that could prevent a release such as man made berms dikes and barriers does not exempt a facility from needing an spcc plan 40 cfr 112 1 d 1 i.

Double wall storage tanks and secondary containment systems provide protection against hazardous chemical spills double wall tanks imt provide the best protection against hazardous chemical spills into the environment.

It is a good idea to ask the manufacturer whether your tank fulfills this requirement.

This is in response to your letter of december 28 1992 in which you requested from the occupational safety and health administration osha an interpretation on whether the use of double wall above ground tanks is acceptable for secondary containment of flammable and combustible liquids in place of diking to meet the requirements of 29 cfr 1910 106 b 2 vii.

Part of using a double wall fuel tank is making sure it is up to industry standards.

Subpart i use and management of containers 40 cfr 264 175 which covers portable storage containers such as 55 gallon drums for hazardous waste and the second in subpart j tank systems 40 cfr 264 193 which covers large stationary containers.

When using open containments you have to deal with leaves dirt and debris which will enter the containment.