All c v belts have a standard 7 8 width and lengths range from 40 up to 555.

C section v belt dimensions.

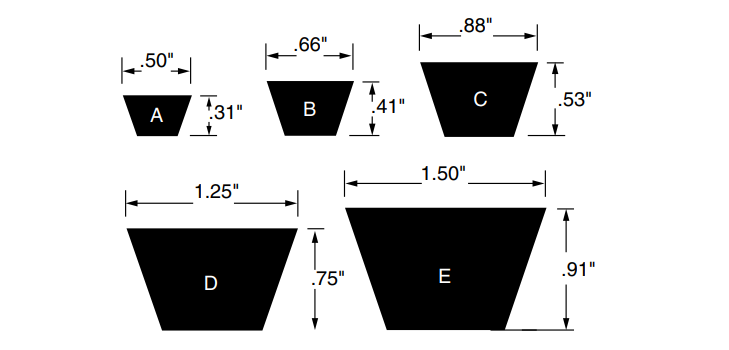

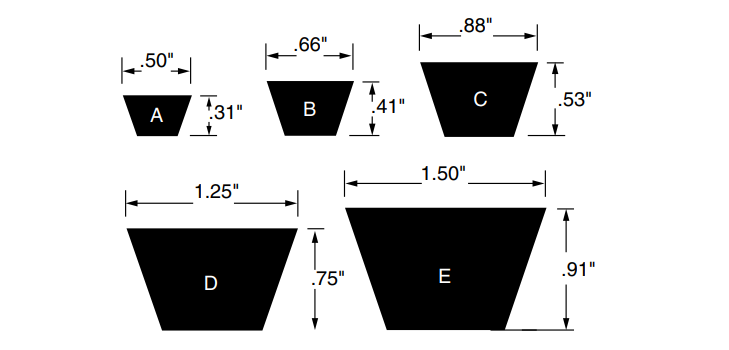

You ll also need to measure the width and depth to determine which section v belt you have.

The c series v belts is a commonly used belt in many industries such as hvac industrial agricultural material handling and much more.

3l section 3 8 width x 7 32 depth.

Classic c v belts are measured on the inside diameter.

Ap s 025 se a min.

The speed ratio would be stable if slippage did not occur.

Standard v belts are manufactured from a special formulated rubber and reinforced high strength polyester cords for uniformity strength.

Originally designed to replace leather belts in a variety of industries including agriculture rock crushers mining and lawn garden.

Belt section pitch diameter m 0 33 bg hg min.

Simply add the length from step 3 and you have the required size.

A 4l section 1 2 width x 5 16 depth.

A ratio is a proportional factor between two similar objects of different sizes.

C109 has a 113 inch outside length.

Measure the section with a ruler measure the top width of the belt widest part of the vee and then the thickness of the belt.

In a belt drive system a ratio is used to determine the speed relation between two v belt pulleys.

Ax section cogged 1 2 width bx section cogged 5 8 width cx section cogged 7 8 width fhp belts.

Buy c section v belts now.

Classic a section v belt.

Classic kevlar v belt sections.

A special outer wrap is used on the belts which provides better flexibility better traction and wear resistance.

B 5l section 5 8 width x 13 32 depth.

These are used in many industries such as industrial agricultural material handling hvac and much more.

3l section 3 8 width 4l section 1 2 width 5l section 5 8 width wedge v belts.

7 8 c classic v belts classic c 7 8 top width v belts are exactly that classic in design and application.

Click here for more complete specifications per belt section.

However as belt slip is inevitable the ratio varies and is therefore only theoretical.

A section 1 2 width b section 5 8 width c section 7 8 width d section 1 1 4 width e section 1 1 2 width classic cogged v belts.

3v section wedge 1 2 width.

L pitch length of belt c center distance d diameter of large sheave d diameter of small sheave solution 84 belt using the information from step 1 and 2 we determined that we had a b section in the notched style x or combined a bx belt.

The width ranges from 1 2 up to 1 1 2 and lengths from 16 up to 400.